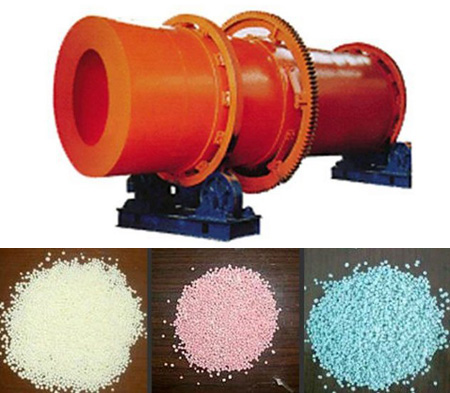

Rotary drum granulator is very versatile equipment in the metallurgical and fertilizer industries. Compared with disc granulator, there is no output size classification. A drum fertilizer granulator is composed of an inclined cylinder. The inlet of granulator with stud ring prevent overflow, while the feed outlet has also stud ring to ensure materials layer depth. The materials mixed by mixer are quantitative into cylinder automatically and touch with the spray of droplet. Due to cylinder constant rotating, the materials are gradually formed into small balls. With materials adding, the fertilizer pellets are continuously discharged. The cylinder wall is equipped with scraper to avoid materials sticking on the cylinder wall.

Rotary Drum Granulator

Technical Parameters:

|

Model |

Diame

ter(mm) |

Length

(mm) |

Dip(○) |

RPM

(r/min) |

Output

(t/h) |

Power

(Kw) |

|

ZG1.2*6 |

1200 |

6000 |

3 |

5 |

0.5-1 |

5.5 |

|

ZG1.4*7 |

1400 |

7000 |

3 |

5 |

2-3 |

7.5 |

|

ZG1.6*8 |

1600 |

8000 |

3 |

5 |

3-5 |

11 |

|

ZG1.8*9 |

1800 |

9000 |

3 |

4 |

4-5 |

15 |

|

ZG1.6*10 |

2000 |

10000 |

3 |

4 |

6-8 |

18.5 |

Why Choose Drum Granulator of KMEC?

|

-

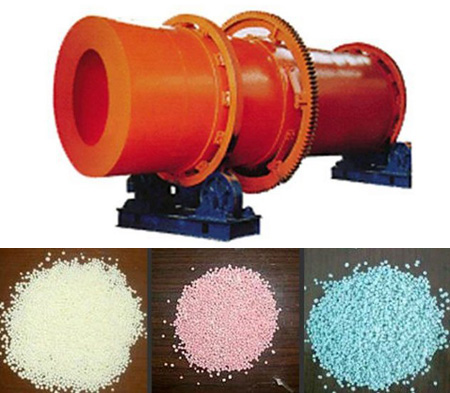

Granulation rate can reach about 70%. Several of reverts with small granularity are available for new granulation.

-

Adopting vapor for material heating, the final fertilizer granules is low moisture content. So this reduces the pressure of dryer and improves production efficiency.

-

The inner drum granulator is lined with good corrosion resistance and heat preservation capability, which can prevent materials from sticking into the drum wall. As a result, drum granulator made from KMEC not reduce labor intensity but prolong the service life of fertilizer granulator.

-

Simple operation, large production, low consumption and easy maintenance.

|