price and high quality

Compound Fertilizer Granulation Equipments ?

KMEC is your right choice!Compound fertilizer is an essential factor for the crops, which can provide enough nutrition to meet the growth of crops. According to the latest data shown, The needs of compound fertilizer pellet is an increasing trend annually for farmers. While few people know how compound fertilizer pellets are produced. Do you know how to select compound fertilizer granulation equipments? Follow our words to find the answer you wanted.

Compound fertilizer contains two or more essential nutrients like main nutrients, secondary nutrients, trace elements etc.. The compound fertilizer is divided into organic and inorganic fertilizer. Organic compound fertilizer has a wide range materials such as manure, fish, bone meal as well as compost. While inorganic fertilizer is added various chemical elements in the manufacturing process. Combinations for different crops and growing conditions are produced.

- Fertilizer

- NPK-Compound-Fertilizer Production-Line

- Compound Fertilizer pellets

Compound fertilizer granulation plant is made up of disc mixers, belt conveyor, vertical crusher, disc granulator, rotary drum granulator, rotary cooler, rotary dryer, elevator, packaging machines, high-temperature materials drying equipment and fertilizer coating equipment. These devices are all manufactured in accordance with the standards of Ministry of Chemical Industry.

Above two projects are the cases that we have successfully designed. If you have any better suggestions and requirements, we can provide you with a more detailed program.

Compound fertilizer granulation is the most important equipment in the compound fertilizer granulation plant .Different granulation has the different yield, we will introduce two typical granulations for you.

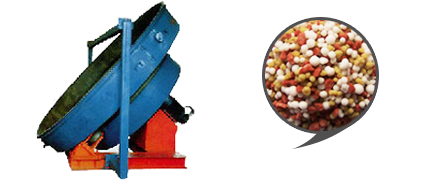

Disc granulator has the following characteristics: high granulating rate, homogeneous grain, high strength, convenient operation and easy maintenance, etc.

The slope degree of its pan is adjustable, and the amplitude ranges from 40° to 55°.

It is ideal for small scale fertilizer production of medium and low concentration.

Working principle

Driven by a motor, the pan revolves at a certain angle with the horizontal plane. Friction between the powder and the pan causes the powder rise, but gravity makes it fall back down. Meanwhile, centrifugal forces make the powder fly to the edge of the pan. The combination of these three forces will make the powder roll in a certain trace. It will then be gradually granulated into the required size and fall off at the edge of the pan.

Technical Parameters:

| Model | Diame ter(mm) |

Length (mm) |

Dip(○) | RPM (r/min) |

Output (t/h) |

Power (Kw) |

|---|---|---|---|---|---|---|

| ZG1.2*6 | 1200 | 6000 | 3 | 5 | 0.5-1 | 5.5 |

| ZG1.4*7 | 1400 | 7000 | 3 | 5 | 2-3 | 7.5 |

| ZG1.6*8 | 1600 | 8000 | 3 | 5 | 3-5 | 11 |

| ZG1.8*9 | 1800 | 9000 | 3 | 4 | 4-5 | 15 |

| ZG1.6*10 | 2000 | 10000 | 3 | 4 | 6-8 | 18.5 |

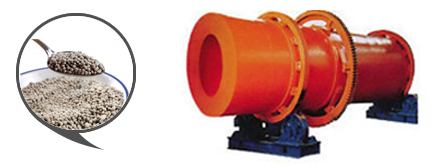

The cylindrical body of our drum granulator is made of a special stainless steel or rubber plate lining.

Our drum granulator has the features of high productivity, high intensity of granule, low energy consumption, erosion proof, abrasion proof, long service life, convenient operation and easy maintenance, etc. It is suitable for large scale fertilizer production of high, medium and low concentrations.

Technical Parameters:

| Model | Diame ter(mm) |

Length (mm) |

Dip(○) | RPM (r/min) |

Output (t/h) |

Power (Kw) |

|---|---|---|---|---|---|---|

| ZG1.2*6 | 1200 | 6000 | 3 | 5 | 0.5-1 | 5.5 |

| ZG1.4*7 | 1400 | 7000 | 3 | 5 | 2-3 | 7.5 |

| ZG1.6*8 | 1600 | 8000 | 3 | 5 | 3-5 | 11 |

| ZG1.8*9 | 1800 | 9000 | 3 | 4 | 4-5 | 15 |

| ZG1.6*10 | 2000 | 10000 | 3 | 4 | 6-8 | 18.5 |

Remark: if the process and raw material are different, it will affect the yield, grain rate and the diameter of the grain.

Add: Suite C, 4/F, Jinhao Business Bld., Renmin Rd. Anyang, Henan, P.R.C.

Tel: 0086 372 5965149

Fax: 0086 372 5951936

E-mail: info@pelletfertilizer.com